You certainly know someone who patches up things that have gone wrong, only to do it all over again in the near future. Don’t you? So what can you do to avoid making a similar mistake with your own problems? Employ a few causal analysis tactics and you’ll be set.

The Effective Technique to Problem Solving: Causal Analysis

Causal analysis, also known as root cause analysis or cause-and-effect reasoning, is a popular and effective problem-solving technique designed to help you understand precisely why the problem occurred and how it can ultimately be fixed for good. It’s a popular concept that has been discussed at length in the book Root Cause Analysis : A Tool for Total Quality Management.[1] For example, instead of simply repainting your wall, you’ll use causal analysis techniques to work out that the wall is damp, then why the wall got damp in the first place, and ensure your costly repair job is actually going to be the end of the problem for good.

The simplest way to look at a problem using causal analysis is to ask ‘why’ five times.

Obviously, some problems will take more or less than five times to uncover the reasons behind them, but on the whole using five times as a rule should help you remember to dig deeper every time you’re analysing the root cause of a problem. So, instead of saying “There’s a problem with my resumé “, you would ask “Why?” five times and get an answer something like this: There’s a problem with my resumé. Why? Because I’m not getting the job offers I want. Why? I keep getting offered sales positions, when I want marketing jobs. Why? Because all my previous jobs were in sales. Why? Because no-one knows I’m good at marketing. Why? Because I never made that clear on my resume, I just listed the previous jobs I had. Bingo, you have the answer!

But causal analysis can go wrong if you make the wrong presumption.

Although this is a great technique, things can go wrong quickly with causal analysis. How? Well, what happens when you make the wrong presumption? If you think something is a cause of something else, but it’s actually just tangentially related, then you get to the wrong answer. And fast. Say for instance you’re trying to diagnose your common cold symptoms, and you happen to be Googling for help. You could easily go through a process much like this. I’ve got a runny nose. Why? Because I’ve got an allergy to something. Why? There must be pollen in the air. Why? My windows are open, but the pollen is inside. Why? It’s windy outside. Why? Because of the season. This could lead you to presume you’re always going to have seasonal allergies, and to buy the wrong sort of medication to deal with your problem. Or perhaps you might shut the window and presume the symptoms will go away now that the pollen can’t get into your house. Either way, you haven’t come to the right conclusion.

No, Dr House, it’s not Lupus.

Go one step further with a fishbone diagram.

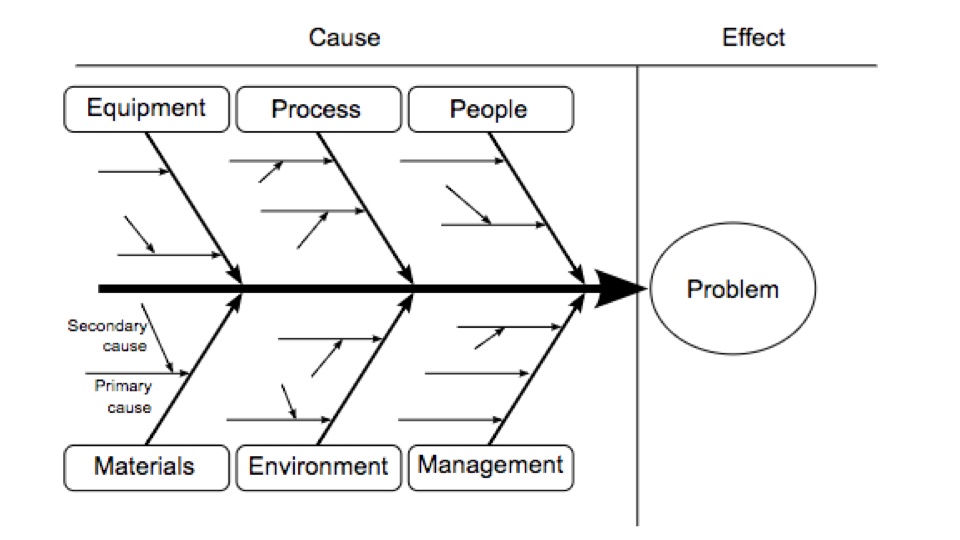

If you’re getting pretty good at analysing your problems, you can take it a step further by noting the root causes on a fishbone diagram. This is the ultimate technique to tackle the really big problems you might face on occasion, such as ones you might face when problem-solving for your business. These fishbone diagrams, also known as Ishikawa diagrams, are an effective way of streamlining your thoughts, then mapping each possible cause pathway so that each possibility can be tested and eliminated one by one. They’re very effective for teams to use when focusing their brainstorming, and to get group thinking out of ruts.

Image Credit: Fabian Lange

In business, these Ishikawa cause-and-effect diagrams are often used to map out possible reasons for product defects. In fact, they were first created to track quality management issues in the Kawasaki shipyards. In this sort of situation, the possible causes would be grouped to track causes related to people, methods, materials, machines, etc.

Within each group, each possible cause is noted and then you follow the previous technique of using the five whys to determine the root cause. In the diagram, this is portrayed using little arrows to show the path of causation of each item.

This effective problem-solving technique can be used in just about any industry or facet of life you can think of.

It’s so easy to train yourself to think more deeply through the causes of your problems, why wouldn’t you do it? The causal analysis method is also used in quality assurance management professionals to ensure critical problems do not reoccur. If professionals trust this simple, yet effective method of working through problems, you should probably give it a chance yourself. So, always remember to ask yourself “why” five times. Featured photo credit: Stocksnap via stocksnap.io